allied machine and engineering speeds and feeds

Cutting is a balance between a number of factors - cutting slowly will add costly time to manufacturing operations. Allied Machine and Engineering has released the Wohlhaupter VolCut insert holder an expansion of its boring line.

MMSOnline uses the tagline Achieving high metal removal rates with quick milling passes for the HSM zone on their site.

. I am drilling a 25mm hole 11 deep the recommendation is 180- 240 sfm and 008-009 Feed. The speeds and feeds listed above are a general starting point for all applications. Machining reasonable speeds and feeds for a single cutting point tool table.

Allied Inserted Drills. Machining reasonable speeds and feeds for a single cutting point tool table. I am having some trouble with drilling into 316 SS almost every hole size and depth.

After plugging these values into the equations below the adjusted internal feed becomes 28 IMP while the external feed becomes 138 IPM. Posted April 25 2008. AlTiN is highly recommended for steel stainless steel high temp alloy.

Another very high tech definition of HSM is Machining at the Resonant Frequency of the Machine which goes to HSM techniques for selecting spindle speeds. RPM SFM x 382 divided by tool diameter. Setup and machine rigidity may affect performance.

It can be used on serrated tool bodies and Alu-Line slide tools in the diameter range from 3937 12815 100 mm 3255 mm. Feed the longer drill within 116 15mm short of the established pilot hole bottom at a maximum of 50 RPM. To ISO 90012008 Open the catalog to page 1 Our focus on product excellence service to the customer respect for the individual and competitive advantage enables us to deliver outstanding results in a diverse range of manufacturing.

The thread diameter of a 916 thread is 562 which is used for the inner and outer diameter in both adjustments. Allied Machine and Engineering has released the Wohlhaupter VolCut insert holder an expansion of its boring line. There are many definitions for High Speed Machining HSM.

ENGINEERING CDRP Allied Drilling Products Allied Machine Engineering Corp is Registered by UL. Manufacturing Design and Engineering. The proper speed and feed help improve tool life and remove material at the optimal rate.

12 IPM 300 mmmin Details. Allied Machine Engineering Corp is a leading manufacturer of holemaking and finishing tooling systems. Im not sure that a spade drill is going to be really happy going into a radiused surface but if you have experience with it Ill defer to you because I dont.

Recommended Speed and Feed Example. People in management have little understanding on whats happening on the shop floor and do not like to listen to criticism. SpeedFeed 10xD 200 SFM 080 0008 IPR 080 160 SFM 00064 IPR.

AccuPort 432速 Port Contour Cutters Recommended Speeds and Feeds Metric IMPORTANT. Road Ready Drum and Machine Components. If recommended speed and feed is 61Mmin and 020 mmrev for a 3 x diameter or 5 x diameter holder then the speed.

The calculated speed is 2064 RPM and the linear feed is 83 IPM. Allied Machine and Engineering 452H-0112 1-38 Diameter x 316 Thickness 132 Degree Included Angle AM200 Super Cobalt GEN2 T-A Series Spade Drill Insert. I cant get anywhere close to the feed because my machine has not the power to do it i get a servo alarm.

Additionally this precision boring tool can be adjusted without the aid of the readout. Great place to work but management is terrible. 020 mmrev 080 016 mmrev.

Allied Machine Engineering Corp. One of Niagaras rules for adjusting speeds and feeds is when the Axial Depth is between 025 to 05 Tool Diameters use 80 of the lowest SFM range. Engineering Calculators Miscellaneous Calculators Speed and Feed Calculator.

The boring system combines the modularity of the Wohlhaupter MVS connection with the companys large. Do you want to enter one or more of your machine limits. Allied devotes its advanced engineering and manufacturing capabilities to create the widest selection of value-added tooling available to metal-cutting industries around the world.

Allied Machine and Engineerings website has feed and speed recommendations for their spade drills here. Find SFM IPM RPM and more here. But when Axial Depth is equal to or greater than Tool Diameter use 80 of the highest speed range.

The speeds and feeds listed below are a general starting point for all. Allied Machine Engineering Corp is a leading manufacturer of holemaking and finishing tooling systems. SFM Surface Feed per Minute.

The rough boring system removes large volumes of material at high speeds and light feed rates in just one cut the company states. Determine the spindle speed RPM and feed rate IPM for a drilling operation as well as the cut time for a given cut length. Refer to the coolant recommendation charts for coolant requirements to run at the.

Utilize a pilot drill with the same or larger included point angle. Designation 2 GEN2 T-A SC AM200 1-38 Type. Allied devotes its advanced engineering and manufacturing capabilities to create the widest selection of value-added tooling available to metal-cutting industries around the world.

Working at Allied Machine can be enjoyable most days but on other days it is a mess caused by poor planning and management. Establish the pilot hole using the same diameter short drill to a depth of 2xD minimum. Our tooling solutions deliver the lowest cost-per-hole in a wide range of drilling boring reaming.

Allied - Allied Machine and Engineering - Industrial Holemaking Cutting. 58 to 60 RC. Pitfall 3 No Interpolation of the Manufacturers Data.

Speed Adjustment Value. 200 SFM 070 0008 IPR 070 140 SFM 00056 IPR. Drilling operations are those in which a cutting tool with sharp teeth such as a twist drill rotates and feeds into the workpiece axially forming a hole with a diameter equal to that of the tool.

Made of hardened steel it is extremely robust and resistant to all external mechanical influences. Our tooling solutions deliver the lowest cost-per-hole in a wide range of drilling boring reaming. The rough boring system removes large volumes of material at high speeds and light feed rates in just one cut the company states.

Allied Machine Offers Exciting Program Of Technical Education Seminars Aviation Pros

Thread Milling Threading Allied Machine Engineering Pdf Catalogs Technical Documentation Brochure

Allied Drilling Products Catalog Allied Machine Engineering Pdf Catalogs Technical Documentation Brochure

Allied Drilling Products Catalog Allied Machine Engineering Pdf Catalogs Technical Documentation Brochure

Allied Machine Opens Ohio Training Center Aerospace Manufacturing And Design

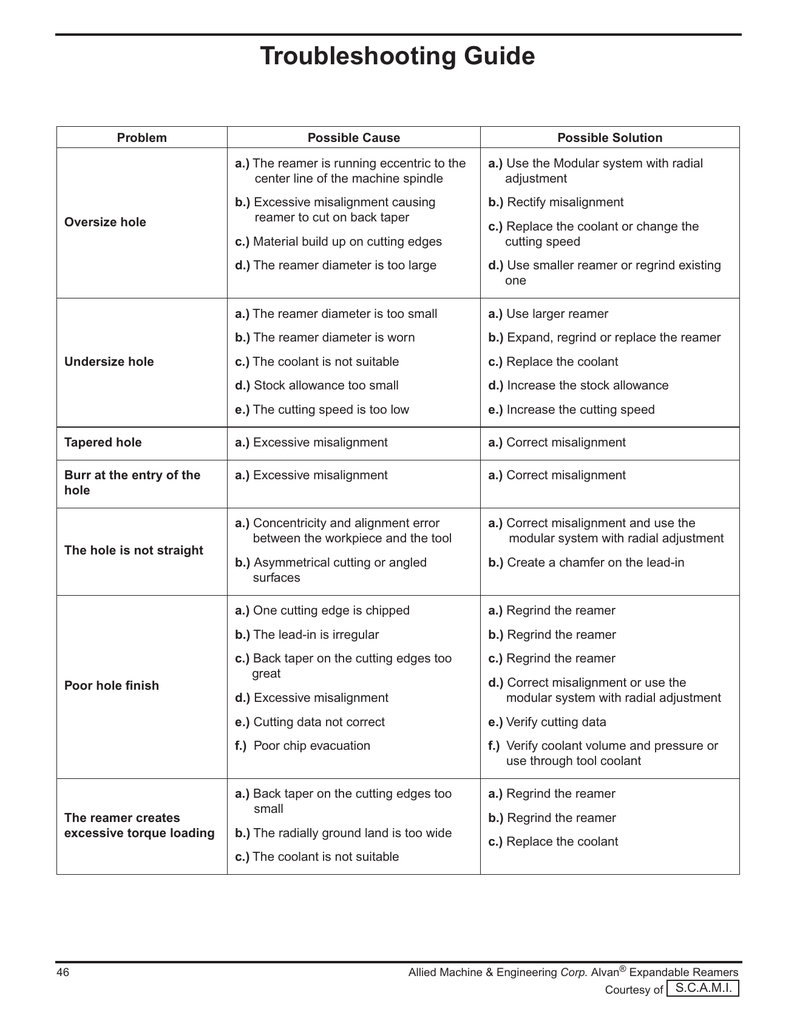

Troubleshooting Guide Allied Machine Engineering Corp Manualzz

Allied Machine Engineering 25005h 003is044 Hardened Tool Steel Structural Holder Helical Flute Taper Shank 11 16 Drill Insert Range 6 1 2 Drill Depth 13 5 64 Length Amazon Com Industrial Scientific

Allied Drilling Products Catalog Allied Machine Engineering Pdf Catalogs Technical Documentation Brochure

Allied Machine And Engineering Tm75010 0 495 Diameter X 0 500 Shank X 1 25 Loc X 3 5 Oal 4 Flute Tiain Solid Carbide Helical Flute Thread Mill All Industrial Tool Supply

Allied Drilling Products Catalog Allied Machine Engineering Pdf Catalogs Technical Documentation Brochure

Allied Drilling Products Catalog Allied Machine Engineering Pdf Catalogs Technical Documentation Brochure

Allied Machine And Engineering 24000s 075l T A Spade Drill Insert Holder All Industrial Tool Supply

Allied Machine And Engineering Wohlhaupter Volcut Large Diameter Boring Tool Uses High Speeds Light Feeds